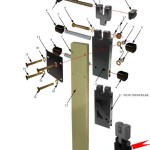

Landing Gear

The landing gear is raised and lowered by an electric pump with a hand pump as a safety back-up.

The wheels raise and lower together on four separate Hydraulic Cylinders. This is yet another safety feature built into Montana’s floats.

Hydraulic system pressure is limited to 600 psi when operating in real flying conditions. However, all hydraulics are pressure tested to 1500 psi prior to installation. After installation, the landing gear is actuated and again pressure tested to 1500 psi.

All of the working parts in our landing gear are bushed with space-age material that requires no lubrication.

This makes the gear low-maintenance and ideal for the harsh environment where amphib floats operate.